News

We Did It! ACOMAR Wins Innovation Project of the Year 2024!

ACOMAR Wins Innovation Project of the Year 2024!

SubC Partner Nominated for Innovation Project of the Year 2024!

SubC Partner Nominated for Innovation Project of the Year 2024!

SubC Contributes to Green Hydrogen Technology with Green Hydrogen Systems' X-Series

SubC Contributes to Green Hydrogen Technology with Green Hydrogen Systems' X-Series

SubC invests in the talents of the future

SubC invests in the talents of the future

SubC Partner Expands

SubC Partner Expands with Acquisition of Sahara 4

Pioneering Green Energy Storage

Pioneering Green Energy Storage

SubC Partner Nominated for EY Entrepreneur of the Year Award

SubC Partner Nominated for EY Entrepreneur of the Year Award

Opkøb af SH Group Esbjerg

SubC Partner erhverver SH Groups afdeling i Esbjerg

Everfuels PtX facility

Prefabrication and subsequent installation of piping and piping supports.

An inspirational visit

Yesterday was an inspiring day! Thank you to TotalEnergies Innovation Management Team.

Our Global Business Partner

Baker Hughes - Global Business Partner.

Virtual Customer Workshop. Thank you for a successful day!

Fabric Maintenance Contract

SubC awarded a long-term, Fabric Maintenance Contract for TotalEnergies in Denmark with our partner Altrad.

Inspection

The lack of volume between the blocks and the pier head was measured systematical. We performed scanning, analyzed the data, and made drawings.

CERN

CERN the world's largest physics laboratory.

SubC take over Norsea's manufacturing division

NorSea and SubC to strengthen collaboration

Crossbridge Energy Turn Around

SubC awarded the mechanical scope of TA on Crossbridge Energy

Nyt partnerskab

Nyt partnerskab indenfor spirende Power-to-X Industri

Replacing carbon steel pipes with GRE pipes

Replacing carbon steel pipes with GRE pipes at one of our customers site

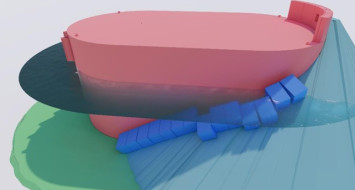

ACOMAR a subsea robot

As part of the ACOMAR project, we have tested several cleaning tools at the Port of Esbjerg.

Årets Ejerleder 2020

We believe in innovation and growth opportunities in spite of COVID-19. Well done to all at SubC.

JibFlex improves safety in lifting operations

Where no conventional lifting beam can operate due to limitations of space.

ACOMAR

A new subsea robot, ACOMAR, is under development to remove marine growth safe and cost-effective.

Removal of the IPF monopile and its caisson

Pioneering Spirit removed the 7,800 tonne TWA topsides, but this couldn't be done before removing the IPF monopile.

Intelligent cutting 3 metres below seabed

Dredging and cutting of steel structures 3 meters below seabed using Abrasive Water Cutting.

We are serious about constantly improving SubC

Being a part of the Next Step Challenge process has resulted in an optimized strategy.

Officially a Board Member of SubC Partner A/S.

Patrick Gilly has served as a strategic leader, most recently as Managing Director of Total E&P Denmark.

Winner of the Award "the most scaleable company of the year" 2020

We believe in innovation and growth opportunities. Well done to all at SubC.

Winner of the Scale-up Award in the offshore category

The competition of the best potential, the best idea and the best team.

ATEX Zone 2 JibFlex

Designed as a highly durable and flexible solution, it improves lifting operations and makes workplaces a safer place.

Adapter Cover

Design, fabrication and installation of the circular steel plate. Simple, robust and cost-effective design for safe storage and lifting.

Bearing Blocks Campaign II

Fabrication and installation of 24 lifting points for Tyra. Responsible for the preparation including project management and engineering.

Successful load test of 2 TP cover racks

An urgent job for a good customer. Two TP cover racks designed and produced by SubC.

Installation of bunker lines on the loadout site

After the excavation for the bunker lines, the installation of the bunker lines was carried out.

Dump caisson inspection

The dump caisson for produced water was leaking directly up against the monopile and the monopile urgently had to be inspected.

New anchoring solution for H-beams

New JibFlex solution. Currently, we are working on a new standard anchoring solution for H-beam.

Gangway designed for extreme wind conditions

Design, Engineering, Fabrication and Installation of aluminium gangway designed for extreme wind conditions.

Glass Fibre Reinforced Epoxy

We are pleased to have recently been certified as Glass Fibre Reinforced Epoxy (GRE) specialists.

ROV operation

We conducted an ROV operation to determine if the jacket structure was damaged, especially horizontal braces. Without the use of divers or RAT.

Bearing Blocks Campaign

Fabrication and installation of 24 lifting points for Tyra. Responsible for the preparation including project management and engineering.

Splash Zone Painting Campaign

A good working relationship ensured that the job was completed within the time frame despite the weather.

Chemical Injection Module, multidiscipline fabrication

Johan Sverdrup - SubC was awarded the full fabrication, assembly and testing contract.

A new, flexible JibFlex solution for MacArtneys workshop

The advantage of this new solution is particularly the lifting height.

Flare Access Platform replacement in the Danish part of the North Sea

Due to thermal stress issues, the original platform was replaced.

New JibFlex solution - moving faulty motors on a wind vessel.

A 4 modules solution moving 1 ton with the flexibility of 1.2 metres.

See how easy the assembly and disassembly of the JibFlex is.

It took us roughly 5 minutes to assemble and disassemble the JibFlex.

A successfull project for Vattenfall

A successful project for Vattenfall – the Jibflex is adding efficiency and safety to manual handling.

Marine Growth Preventer (MGP) rings

MGP rings is a simple solution driven by wave energy removing marine growth and prevent regrowth.

Boat Fender for Tyra West E. Ready for 3D and coating.

31,2 tonnes Boat Fender for Tyra West E. A great welding job. Ready for 3D scan and coating.

Weld & epoxy project

Ensuring a long lifetime. Uninstalling seals on one caisson is ongoing after successful epoxy injection.

JibFlex Train the Trainer Course

JibFlex Train the Trainer Course - going from knowing little to much in 3 days, we are supporting our customers

EY Entrepreneur Of The Year 2019 - Norminee

SubC is very proud of announcing we have been nominated for EY Entrepreneur Of The Year 2019.

The Spider Deck Clean-Up Campaign

The objective for solving the project was to perform the work in the splash zone without personnel.

Epoxy injection at the Culzean platforms in UK

To ensure a long lifetime for the caissons, it was decided to fill up the gaps to prevent fatigue in the caissons.

The Robotic Jacket Crawler - among top 10 finalists

Among the global top 10 finalists at the Total E&P Best Innovators awards. Read the story; from idea to product.

Installation of Wellhead Access Deck

The installation was a demanding and challenging job, carried out using our special team of rope access technicians.

Diamond Wire Cutter performing circumferential cuts

The removal was done safely and controlled; one section at a time.

Grabber & Diamond Wire Cutter Light in operation

The Grabber & Diamond Wire Cutter Light is lowered from the topside of the platform to the splash zone.

Succesful delivery of TP cover racks

A robust, revolving solution which makes it possible to stack the TP covers. Simple and smart.

Succesful delivery of 4 stairs

We just delivered 4 stairs to use on the tower grillage. Produced in our aluminium department in Esbjerg.

Testing the Cutter

We have just tested a new product called Cutter, which will be used on the Tyra East C for Total later this week.