Field upgrade package

The project

SubC Partner was awarded the complete scope of fabrication of caisson with internal riser array for the 2015 Tyra/Valdemar/Roar/Rolf field upgrade. The project included engineering, testing and transport. Further, fabrication of complete subsea Tie-ins for the project was awarded for subsequent delivery.

Process

SubC was awarded the contract by Technip in April 2013. The scope was to build two upgrade caissons, caisson clamps and all subsea Tie-in spools from the pipeline to caissons. The delivery was for the Maersk Oil operated fields Valdemar and Roar situated in the Danish part of the North Sea.

SubC Partner delivered the first caisson clamps in the summer 2014 and was awarded the offshore installation campaign on both Roar & Valdemar by Maersk Oil. The campaign consisted of the complete offshore installation including chartering of the vessel Stril Challenger, project management, HSEQ & engineering, development of project specific welding procedures, welding, scaffolding, painting, 3D verification and NDE.

Solution

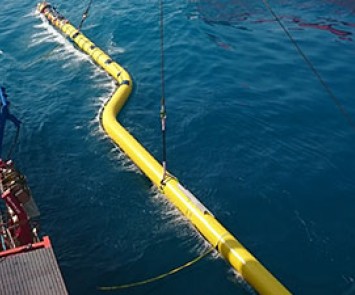

The two caissons – each more than 60 meters and 70 tonnes – was built in less than 20 weeks and delivered almost simultaneously to take advantage of installation vessel in the most efficient way. The fabrication of the complex project required high-performance project management and planning ensuring that the construction was built in the correct and most effective sequence.

The Caisson risers were designed and build according to the DNV OS-F101 pipeline standard to ensure compliance with tie-ins and supersede topside requirements. SubC has extensive experience with this strict standard and delivered the project documentation with an unconditional release note from DNV.

Through our extensive knowledge of metallurgy and welding, we were able to comply with very high demands as set out in the design, while maintaining the cost level and deadline. The teamwork spirit and flexibility of SubC employees once again proved to be a winning formula.

Done on time and without incidents or LTIs.